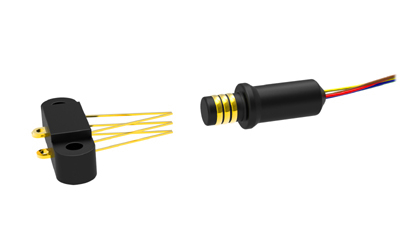

Separate slip ring consists of two parts separately, one part is rotor, another one is brush block, which also could be called split slip ring or PCB design slip ring. One of the rotor part can has through bore type, it uses for liquid channel, pneumatic channel or shaft assembly, which can be specially suitable for space limitations and installation demand in the system of customer. Meanwhile, this kind of separate slipring could use pin instead of lead wire to pass bigger current. Contact materials plays a very important key in the performance of total separate slip rings. Barlin Times adopt the best gold plated contact materials to meet the main performance feature of wear resistant, high temperature resistant, low resistance and so on. If you have specific customized requirement, please feel free to consult us so that our sales engineer could recommend the most suitable product to you for you reference. Specifications:

Product Model

THS-03

THS-04

THS-06

Circuits

3

4

6

Work Speed

0-300RPM

Work Temperature

-20℃-+60℃

Work Humidity

60%RH or higher

Voltage Rating

240VAC/DC

Current Rating

2A or higher

Dielectric Strength

500VAC@50Hz between each circuit

Insulation Resistance

1000MΩ@500VDC

Electrical Noise

1mΩ Min

Contact Materials

Gold to gold

Lead Wire Size

AWG32/28 Teflon® UL

Lead Wire Length

Standard 250mm

Housing Materials

Engineering plastic

Protection

IP54 or higher

Features:

Options:

Applications: